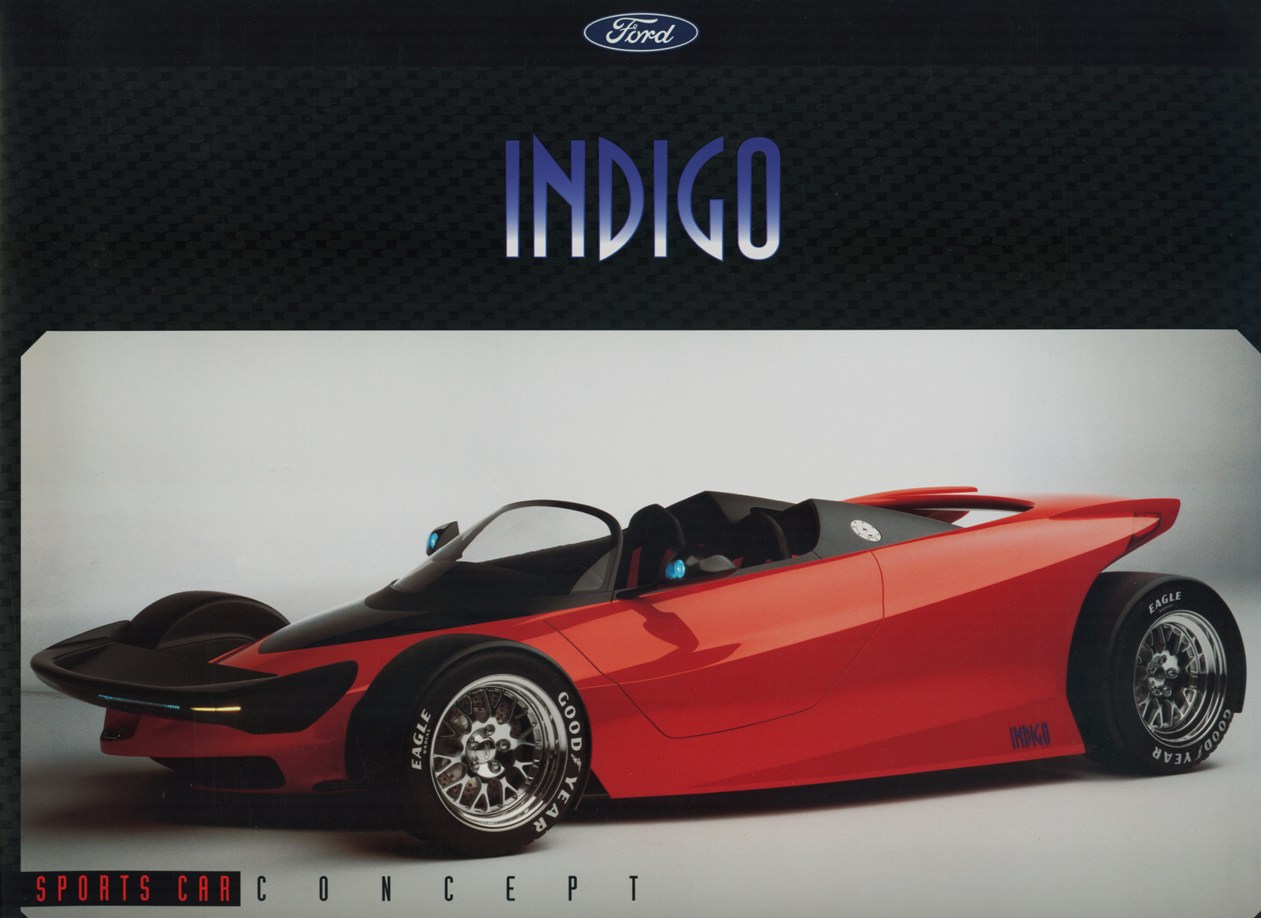

Ford showed this Indigo concept at the international auto shows in 1996. Two examples were built, one non driveable showcar and a fully functional example nick-named 'Go' by the Indigo team. The Indigo combined Ford and primarily Indy car technologies and practices in the areas of materials, construction techniques, powertrain and aerodynamics to create a new dimension in driving excitement by bringing the thrill of the race track to the street.

The chassis, designed in conjuction with Reynard Racing cars, consists of a specially designed central tub formed of a lightweight carbon fiber, aluminium honeycomb composite material. This monocoque chassis differs from a conventional chassis in that it is a one-piece, highly-efficient racing-inspired structure that both forms the Indigo's interior and has the front suspension and running gear attached to it. The rigid construction of the chassis cocoons the driver and passenger in a cell-like structure, with the wide air intake ducts located in the deep rocker panels providing an exceptional level of side-impact protection. Many of the composite components are also being studied to examine their structural properties under stress.

The front suspension -- Indy car-type double wishbones with pushrods operating inboard coil-over shock absorbers -- is fitted directly to the chassis tub. The rear suspension also features double wishbones with pushrods and inboard coil-over shock absorbers and locates directly to the transaxle. Both front and rear suspensions are formed from the same high strength, aero section chrome moly steel tubing that Reynard uses on its Indy cars. The rear suspension arms and geometry are virtually identical to those of an Indy car, while the Indigo's two-passenger tub required the front suspension arms be shorter and have a slightly different geometry than that found on the racing cars.

The basis for the V12 is the current production 3.0-liter Duratec V-6 engine used in the 1996 Ford Taurus and Mercury Sable. It uses the same bore and stroke dimensions (89.0 mm x 79.5 mm) as the Duratec, and also shares its pistons, rings, rods, valves, valve seals, valve springs and retainers. As powerful as the engine is, one of its main features is the abundance of low-end torque. Approximately three-quarters of the V12's maximum torque is available at just 1,000 rpm. The engine is also notable for its fuel efficiency and is expected to achieve over 28 mpg in normal highway driving.

The engine is also bolted rigidly to the chassis' passenger compartment rear bulkhead and also acts as a load-bearing member -- standard practice on Indy cars. The development of the V-12 began prior to the Indigo project and took just 18 months from inception until the first engine was tested on a dyno in September 1995.

The Indigo utilizes a longitudinally-mounted, modified Reynard Indy car transaxle. This unit has six forward gears and a reverse, and features a racing-style, manually-operated carbon clutch. The forward gears are selected sequentially by a an electronic, hydraulic shifter. Buttons on the front of the Nardi steering wheel signal the system to upshift, while alternate buttons on the back of the wheel control downshifts. The clutch must be used on all shifts.

The scissor-style doors are hinged at the front and are raised by lifting them forward and slightly out from the body, allowing the driver and passenger to step down into the car. The car has undergone wind tunnel testing. The results show that enough downforce is being generated by the wings, underbody diffuser and overall body shape to enable the Indigo to corner at a projected lateral acceleration of 1.2g.

The V12 engine is now in production and powers the Aston Martin DB7 Vantage and Vanquish.

No comments:

Post a Comment